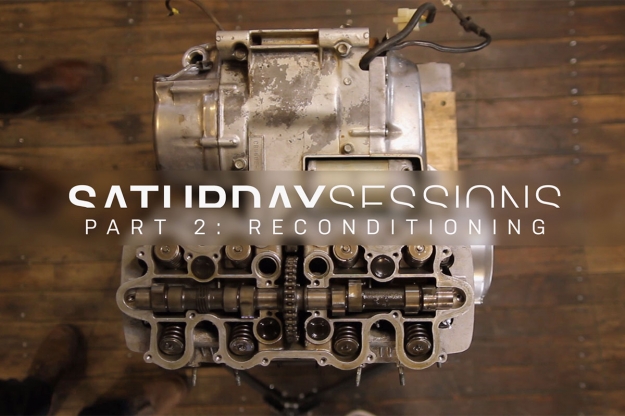

In last week’s Saturday Sessions, we saw E3 Motorcycles tearing down a Honda CB550. This week, it’s time for the messy business of motorcycle reconditioning—inspecting, bagging, and tagging the dismantled parts.

“A nice paint job only tells half the story,” says E3’s David Browning, “and isn’t necessarily a good indicator of overall condition. Time and rubber components don’t play very well together, aluminum oxidizes, and steel gets a bit crusty.”

This CB550 is owned by New York agency Woods Witt Dealy & Sons, and was a lot cleaner than most E3 projects. But it still needs replacement parts—plus all the attention that classic motorcycles typically require.

“We placed our orders for the first round of OEM parts: rubber components, bearings, gaskets, seals, cables and hardware,” says Browning. “Then set to work on the glamorous job of removing 39 years of dirt, grease, rust, and oxidation.”

In this latest video we see the metal parts being prepped for blasting and powder coating, the wheels being disassembled for a full rebuild, and the carbs and front end being readied for an overhaul. We also see the start of the engine breakdown, with covers pulled for polishing. E3 will also be pinning down the source of oil leaks.

“No shortcuts or magic here!” says Browning. “Just a bit of Simple Green, carb cleaner, extra fine #0000 steel wool—and a ton of elbow grease.”

Hit play and enjoy.

E3 Motorcycles | Woods Witt Dealy & Sons | Previously: Part 1: The Teardown