Curiosity is a powerful motivator. When Jack Watkins first spotted Stellan Egeland’s BMW Harrier, he was curious about how the suspension worked—and that curiosity wouldn’t let up. Fast forward nine years, and we have this incredible contraption built around the powertrain of a BMW R1150 RT.

The pseudonymous ‘Jack’ holds a PhD in mechanical design, and works for an industrial firm in Gdańsk, Poland, where he heads up a design office of some thirty engineers. Plus he’s a lecturer and researcher at the Gdańsk University of Technology. So if anyone’s qualified to scratch that sort of itch, it’s him.

It started with Jack figuring out and reconstructing the Harrier’s front suspension design digitally. The design was then shelved for a while, before being resurrected, reworked, and fleshed out into a full motorcycle. Another four years later, and the Watkins M001 was finally complete.

It could have been done quicker—but Jack has work and a family to juggle. So the project was relegated to evenings only. He doesn’t have the experience (or workshop) to build such a machine, either. So he turned to Mateusz Kozlowski at Moto Spec in Gdańsk for help.

The bike’s individual parts came from the network of suppliers and craftsmen that Jack had built up at his day job. But all the assembly and mechanical work was done by the pair at Moto Spec, guided by Mateusz’s knowledge.

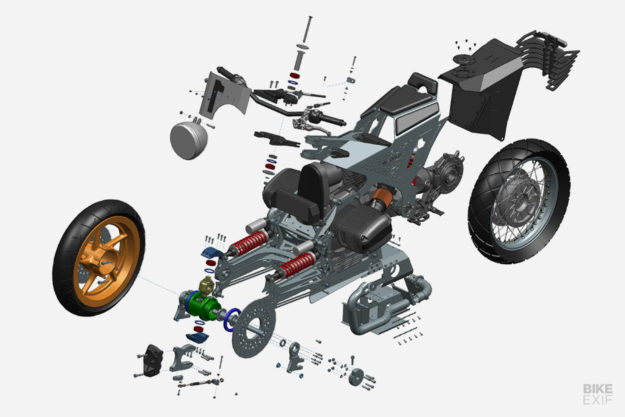

As you can see, the work was extensive. Beyond the power plant and some of the running gear, the Watkins M001 is almost entirely custom-made—like some oversized, mind-bending LEGO Technic set.

At its heart is a 2002 BMW R 1150 RT motor, transmission and final drive. It’s easy to assume Jack sourced an 1150 and stripped it, but in fact he only bought what he needed. “I went to the guy, rode the bike, and just after that we disassembled it,” he tells us. “After a few hours, I had the engine in my trunk.”

The rear shock’s from the 1150 too, but the rear wheel is a BMW GS unit. Up front is a Yamaha XJ6 wheel with a milled hub, hooked up to Jack’s one-off hub-steered front suspension system.

Jack shared several CAD drawings and exploded diagrams of the setup, and we had to lie down afterwards. There are roughly a hundred components in play—including eight roller bearings and ten sliding bearings.

But Jack’s biggest challenges lay elsewhere: the space he had to work with, and the choice of the XJ6 front wheel, which wasn’t an easy fit.

“Despite all the technical problems related to the functional aspects, I wanted to keep it in a different form,” he says. Nevertheless, he checked every last bit by running every simulated test under the sun.

The shocks are from Moto Guzzi V750. “I made an analysis which proved those particular ones would be OK,” says Jack. “I found them at a good price on the internet, as well. That matters when you’re building for yourself after hours!”

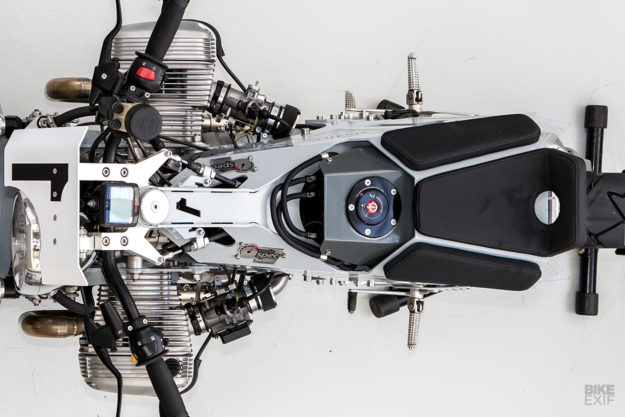

The M001’s main body is essentially two sheets of laser-cut steel, bent in six places—with a few hidden pieces to stabilize the structure. It was impossible to weld up without a jig, so Jack had to design and manufacture that too.

The other trick was to get the mounting points to line up with those on the engine, so there was significant 3D scanning involved.

Hiding under the panels is a small framework that holds the electrical components. Up top, Jack designed three aluminum panels for the seat, sending them to a local craftsman for upholstery.

Everything was designed to tuck together as tightly as possible, to leave space for a generous fuel tank. In the end, Jack managed to squeeze in a 16-liter (4.2 gallon) reservoir—but volume was only half the battle.

“I had to figure out how to carry load from the rear shock through the tank,” he explains. “So inside the tank there is a spatial structure guiding the load to fixing points.”

The fuel pump is mounted in there too, and the filler cap sits just in front of the seat. The rear end is finished off with a unique polycarbonate finned structure, which hides the tank and also provides a mounting system for the taillight and license plate.

Jack says he used steel for the body to save cost, but will use aluminum next time around. “I was not sure if I could fit it all together the first time,” he says. “I was prepared for big mistakes, but it wasn’t that bad after all. Just a few single components had to be scrapped.”

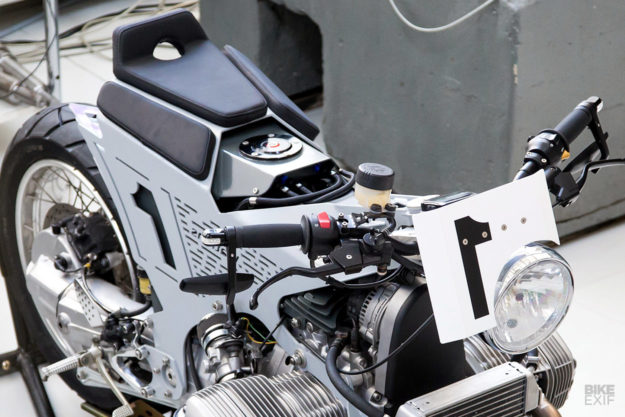

He did use high-strength 7075 aluminum for the M001’s moving parts though, citing safety as a factor overriding cost. And he’s used the same alloy on some less important parts too, for a consistent effect after anodizing. All the components were either CNC machined, or laser cut, milled and bent.

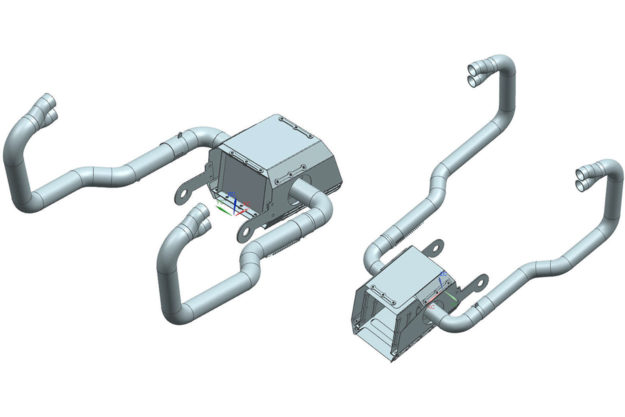

Even the exhaust is excessively complex, and we love it. It’s built from stainless steel, ending in a box that has two layers and eighty-four screws. “It took me almost five hours to assemble it,” says Jack. “The noise is, I would say, unique.”

In contrast, the cockpit’s been kept pretty simple: standard switches of unknown origin, bar-end turn signals and mirrors, and a KOSO speedo. “There is so much happening on the bike that I decided not to go crazy with those details,” he explains. “They simply do not exist when you see the machine.”

The amount of work it took to create the Watkins M001 is as astounding as the bike itself. “The project is complex. The forces are analyzed, the kinematics checked, the material confirmed, the load calculated, drawings prepared, components ordered, online shopping done, the screws are counted… there is every aspect of industrial project inside.”

Jack’s also documented every last detail, which means that if he wants to, he can put together a comprehensive service manual for the M001.

But even with a manual in hand, I’d be too scared to turn even a single screw on this intriguing mechanical animal. It’s the most extreme example of motorcycle engineering we’ve seen since the Subaru-powered Madboxer.

How about you?

Watkins Motorworks | Images by Maciej Bejma.